High-speed steel (HSS) is a subset of tool steels, so-named as they can cut metals at high speed, 3-4 times faster than traditional high-carbon steels. Typically, they consist of carbon steel alloyed with tungsten or molybdenum, together with percentages of chromium, vanadium and cobalt. HSS has many applications such as drilling, reaming, tapping, forming, broaching and milling due to the ease with which it can be shaped in both the soft and hardened state.At room temperature, in their generally recommended heat treatment, HSS displays high hardness (above Rockwell Hardness 60).

HSS tools are strong and heat-resistant, making them durable choices.

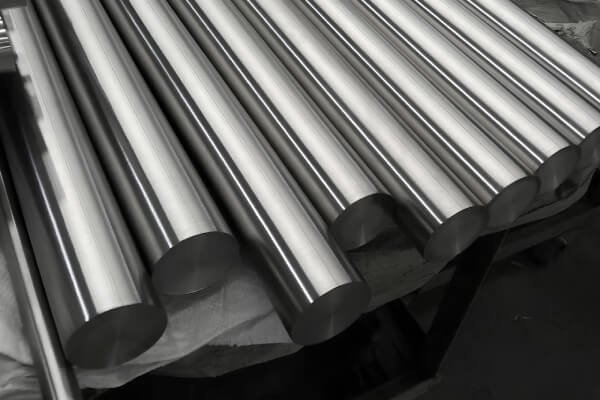

Solid bars or rods are the most common forms of high-speed steels (HSS). Bar stock serves as the starting point for the creation of a variety of cutting tools, including drills, end mills, and reamers.

High-speed steels (HSS) offer numerous advantages, such as:

- Withstands high temperatures (600-620 °C).

- Withstands shock and impact forces.

- High cutting speeds – faster to cut with than traditional alloys like bronze or cast iron.

- Hardness suited for cutting and drilling hard materials.

- Wear resistance for extended tool life.

- It can create precise cuts in various materials.

HSS M2 Grade

Chemical Composition

| Element | Content (%) |

|---|---|

| C | 0.78-1.05 |

| Mn | 0.15-0.40 |

| Si | 0.20-0.45 |

| Cr | 0.20-0.45 |

| Ni | 0.3 |

| Mo | 4.50-5.50 |

| W | 5.50-6.75 |

| V | 1.75-2.20 |

| Cu | 0.25 |

| P | 0.03 |

| S | 0.03 |

Mechanical Properties

| Mechanical properties | Metric | Imperial |

|---|---|---|

| Hardness, Rockwell C (tempered at 1150°F, quenched at 2200°F) | 62 | 62 |

| Hardness, Rockwell C (as hardened, quenched at 2200°F) | 65 | 65 |

HSS M35 Grade

Chemical Composition

| Element | Content (%) |

|---|---|

| C | 0.93 |

| Cr | 4.2 |

| Co | 4.9 |

| Fe | 76.52 |

| Mo | 5 |

| Si | 0.3 |

| W | 6.25 |

| V | 1.9 |

Mechanical Properties

| Mechanical properties | Metric | Imperial |

|---|---|---|

| Hardness, Rockwell C (oil quenched from 1232°C, 5 mins) | 64.8 | 64.8 |

| Hardness, Rockwell C (oil quenched from 1177°C, 5 mins) | 65.2 | 65.2 |

| Hardness, Rockwell C (oil quenched from 1204°C, 5 mins) | 65.2 | 65.2 |

WhatsApp us

WhatsApp us